Kuala Lumpur, Malaysia, October 2016

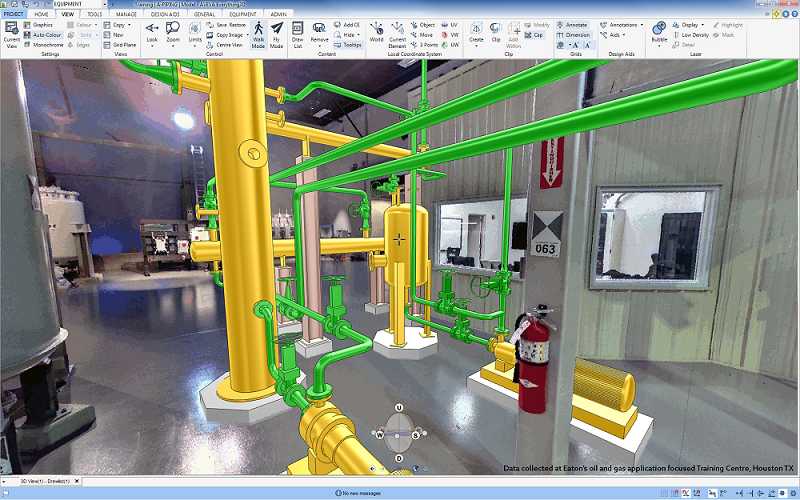

During the 7th Malaysian-French Show Trade about Oil & Gas, organized by PETRONAS and BUSINESS France, Orinox demonstrated the advantages of immersive visualization for review of engineering and training, with a virtual reality headset, to 150 Oil & Gas upstream and downstream professionals. The topic of this presentation was “Driving Efficiency through Collaboration and Innovation”. In the demonstration, guests were invited to immerse in a point cloud, coming from an existing facility. At the same time, based on this point cloud, they saw a 3D design from the engineering department.

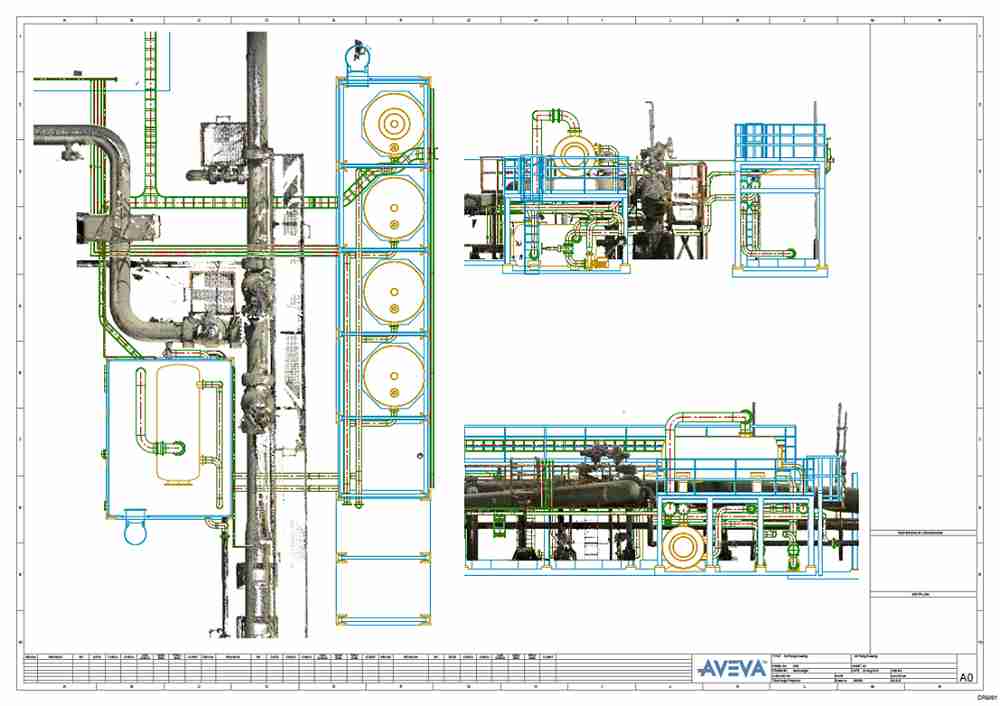

The purpose of this interactive demonstration was to show that the space between pipes can be visually checked, as space for handlingnext by valves or meters. This functionnality also allows users to detect collisions and visualize minimum necessary volumes for handling and lifting cranes. The combinaison of this data set, combined with point cloud and 3D design, is virtual reality ready, where users can comment, share and be access on a WEB browser. The point cloud is part of the digital asset (the digital twin of the real asset) of the Brownfield project, as a 3D model. Up to 40% of the project information is created outside of the design applications. With the point of cloud, it is possible to check a design in an existing plant before delivering all building drawings and before managing construction teams on site.

According to Anil Kumar Malik, Head – Turnaround, Operational Excellence, Centre of Excellence, PETRONAS Upstream, "In the current situation of very low Oil prices, we are trying to be more competitive and looking for technologies and best practices to help us in minimizing our costs without compromising integrity and safety. In my case, I am looking for solutions to minimize the shutdowns of facilities for the maintenance operations. My question is how to do it efficiently and effectively? In this particular event, I meet specialists who are very focused and seeing how they can help us. As the event is divided in 2 parts, listening to experts in the morning, and meeting one to one with vendors and suppliers in the afternoon, this combination is useful. Last, the selection from Petronas and French companies make this event successful."

This solution also reduces operation costs by reducing travel costs on site and by keeping a point cloud which describes the plant "as-is".

The point cloud's advantages

An advantage to the point cloud is the ability to take accurate measurements between points, to evaluate a situation without an expert on site and to share this data for collaborative engineering. The accuracy of the point cloud can throw off the retro-engineering into a 3D model, by engineering directly on the point cloud, by removing volumes of points or by importing 3D models, skid, equipment, objects, machines. Today, 10% of plant construction errors are due to inconsistencies between documents. When the erection of a building wasn’t completed as official drawings are, to rework the drawings without propagating errors can be a real nightmare. A layout of point cloud allows users to find these errors, update corrections and keep documents as a digital asset “as-built” and even “as-is”.

The immersion even allows users to train operators about safety and operation procedures. This meants new operators can become familiarized with the real facility, get “on-the-job” training, be pro-active, look for the tags and equipment, move into the point cloud, while being safe in the training center. The retention of information is even better, from 55% in best case with a traditional training, to 70-90% with an immersive training. These statistic show that this timeof point cloud training will mean on site error and less breakdowns and accidents.

To know more

References:

Orinox and the 3D Data Capture

Orinox and the Industrial Virtual Reality Services

Writer: François MARTINET

Writer: François MARTINET

Position: Business Engineer

Mail: martinet.francois@orinox.com

Linkedin: François Martinet